If you have never tried installing an invisible zipper in a garment, you might be just a wee bit intimidated.

But honestly, I think they are easier to put in than regular zippers, and they definitely elevate the “ready to wear” (RTW) look of your garments.

Invisible zips are best for garments made of light to medium-weight fabric, and should be placed into a garment seam. Nothing exposed for these babies. 😉 Because the “teeth†on invisible zips roll to the under side of your garment, once installed they really are invisible except for the small zipper pull. The zipper teeth are also a bit smaller than those on a “regular†polyester coil or metal zipper, so invisible zips are not commonly used in heavy weight fabrics or in situations that require constant opening and closing. Be sure to buy a zipper that is longer than your opening. You will not be able to stitch beyond the zipper pull, so extra length is extra insurance, and any excess is easy enough to cut off.

I like to put invisible zips into a “flat” or completely open seam, instead of partially sewing up the seam like you would do with a centered, “regular” style zipper. I also think an invisible zipper foot for your specific sewing machine model is definitely worth the investment; truly, it will make the job So.Much.Easier. Although, you rarely have to encourage me to buy specialty machine feet. The “special” engineering that enables them to perfectly perform their function makes these feet worth every penny, IMHO.

So, here are a few tools/supplies that will make the invisible zipper installation job a bit easier. Of course, you will need a sewing machine + basic sewing supplies + an invisible zipper. Duh! 🙂

1. Invisible zipper foot, or (less desirable) a regular zipper foot

2. Fabric marker or chalk marker

3. Interfacing strips

Step 1. Preparing the seam allowance

Finish the edges of your garment in whatever manner you choose. In my sample, I have serged the edges.

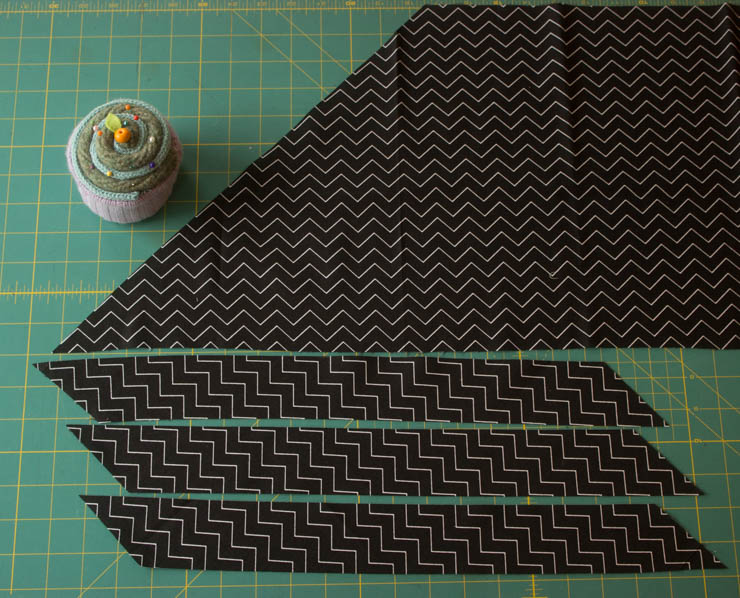

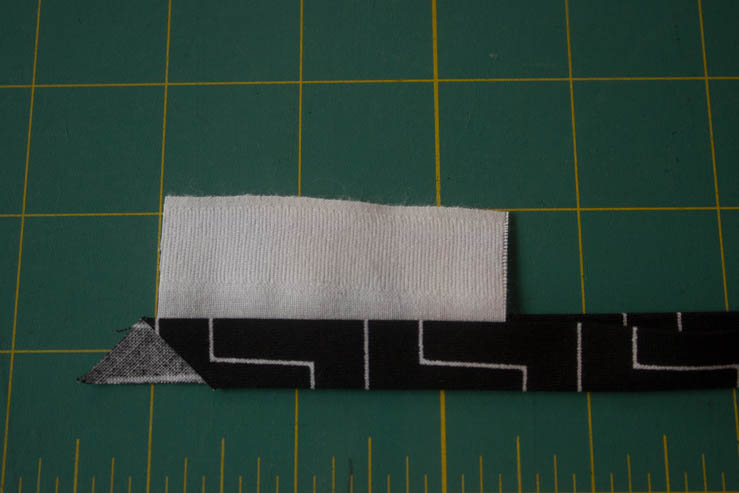

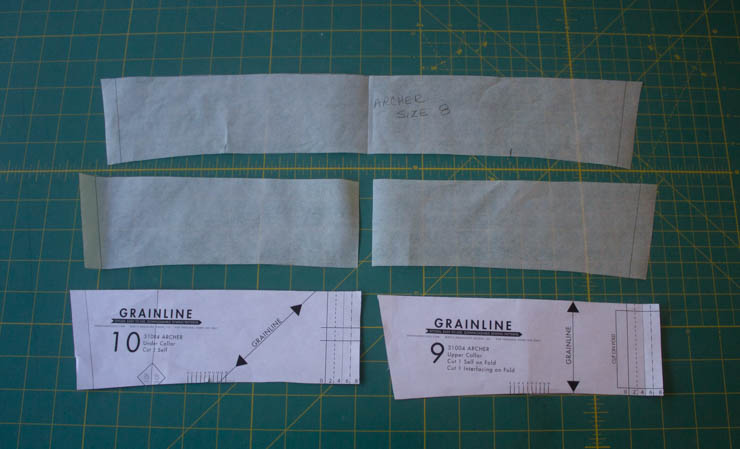

Step 2. Stabilizing

Stabilize the stitching line. I keep strips of fusible interfacing handy just for this purpose. I usually cut the strips about ¾ of an inch wide on the straight grain. Make sure to fuse the interfacing over the stitching line for the full length of the zipper. In my sample, the stitching line will be 5/8 of an inch from the fabric edge, so the interfacing completely covers that area of the fabric.

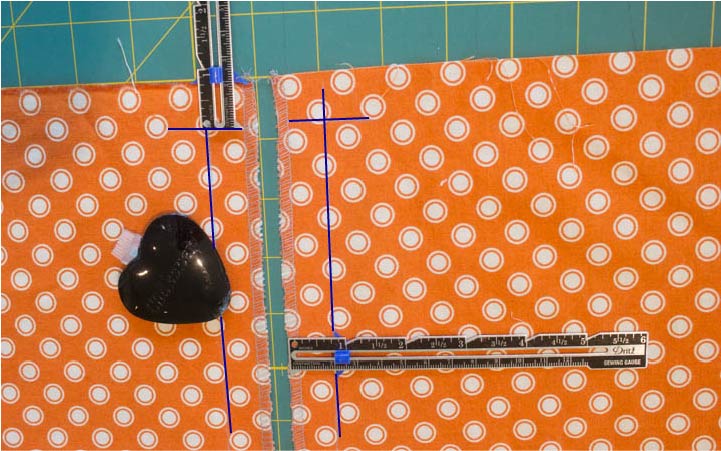

Step 3. Marking

Draw a vertical line on the right side (RS) of your garment that is 1/8 of an inch more than the seam allowance for your garment. In my sample, the seam allowance is 5/8 of an inch, so I drew a line ¾ of an inch from the fabric edge (5/8 + 1/8 = 6/8 = ¾). Do this on both sides of your garment fabric.

This “extra†1/8 of an inch is to allow the invisible zipper teeth to “unroll†while you are stitching the zipper to the fabric.

Also draw a horizontal line 1/8 or ¼ of an inch + your seam allowance from the top edge of both sides of the  garment.

Note: Exactly where you draw this horizontal line depends on how the top edge of your garment is to be finished. If you are adding a waistband, allow only a small amount more than your seam allowance. If you will be facing the top edge and adding a hook and eye closure, add about ¼ of an inch to allow for the “turn of cloth†plus the hook and eye.

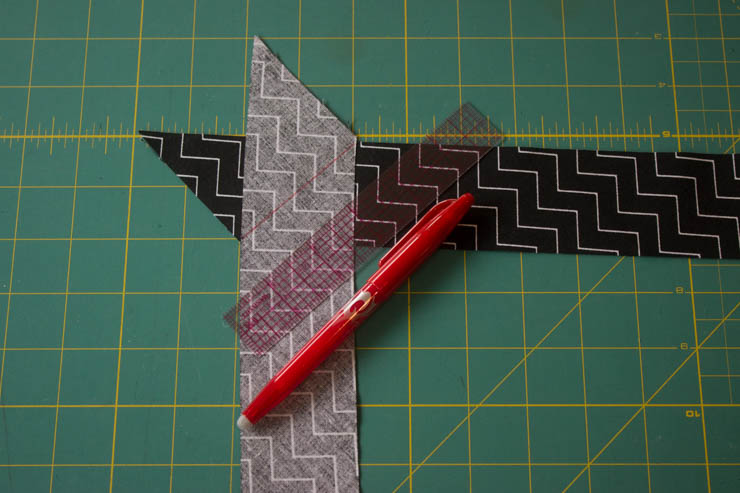

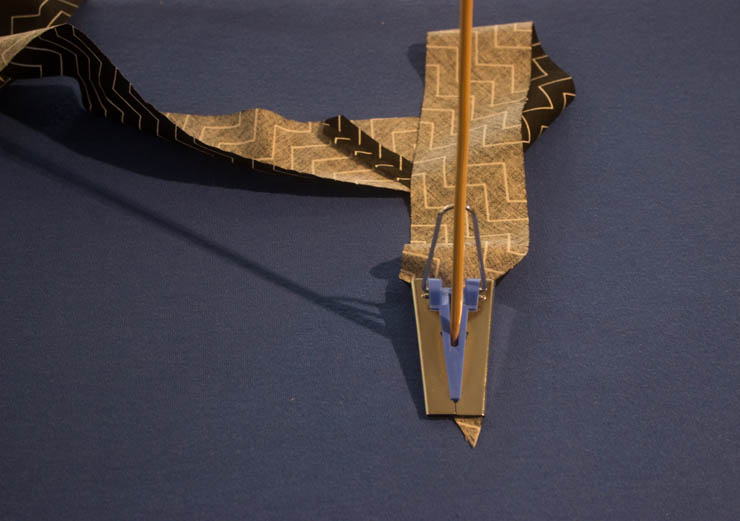

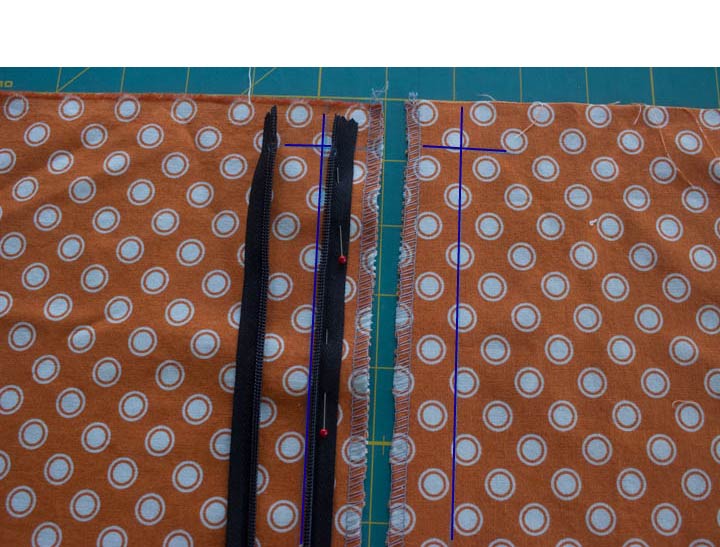

Step 4. Pinning

Lay the open (unzipped!) zipper RS down onto the RS of your fabric, aligning the edge of the zipper teeth with the vertical line and the zipper stop with the horizontal line you drew on the fabric. Pin or baste the zipper to the fabric.

Step 5. First side stitching

Starting at the top edge of the zipper (above the zipper stop), stitch the  first side with a 2.5 or 3.0 straight stitch length. It doesn’t matter which side you stitch first, but since I started on the left side, I am using the left-most side of the invisible zipper foot.

Stitch down as far as you can, or to the marked “zipper stop) point on your garment. To secure the bottom of the zipper edge, you can backstitch for a few stitches, or shorten your stitch length when you are about ½ inch away from the bottom of the zipper.

Note: You can see that it is impossible to stitch beyond the bottom end of an invisible zipper because of the pull size/placement, so using a “too long” zipper is always better than one that is too short. Just stitch as far as possible, or to your marked zipper stop.

Step 6. Second side stitching

Draw a chalk line across the bottom of the zipper where you ended the first stitching line. This chalk line allows you to stop the stitching on the second side of the zipper in exactly the same place as the first side.

Then just repeat steps 4 and 5 for the second side of the zipper, placing the other side of the zipper on the second side of the fabric. Be sure to stop stitching right on the chalk mark!

Step 7. Garment seam closure

Using a regular zipper foot, stitch the remainder of the garment. seam closed. I find it easier to draw the stitching line on the garment first, since I am using a regular zipper foot and have adjusted the needle position accordingly. Be sure to stop your stitching at the same spot as the bottom edge of your zipper stitching, and either backstitch or reduce your stitch length near the end of the seam to secure the stitching.

Step 8. Press

Press your garment! A good press and shot of steam if appropriate for your fabric makes a world of difference in the finished look. Don’t skip this step! Look how perfectly the bottom edges line up!

A few other options….

- If you want a more finished look on the end of your zipper, you can wrap the end of the zipper tape with matching or contrasting fabric. This is an especially good idea if you have cut off some of the zipper length.

- Try securing the zipper tape to the seam allowance only, either for part or the entire length of the zipper. This provides additional security, and also keeps the zipper tape from “flapping†in the seam allowance during wearing.

- If you do not have an invisible zipper foot for your sewing machine, it is perfectly possible to install an invisible zipper with a standard zipper foot. You may to practice just a bit to get the stitching in the correct place so the tape doesn’t show from the outside and making sure the zipper will still “zip up!â€

Do you prefer invisible, or regular zippers? Which do you think are easiest to install?

Happy sewing!

Maris